Catch Defects Early. Keep Production Moving

AI-powered Visual Inspection that detects defects in real time, prevents downtime, and keeps your production running at full speed.

One Standard: Flawless

AI-powered Visual Inspection is transforming how businesses ensure quality across industries - from manufacturing and automotive to food, packaging, and logistics. By combining computer vision and machine learning, it ensures near-zero defects, less waste, and smarter operations that scale consistently across sites.

Smarter Inspection. Zero Compromises

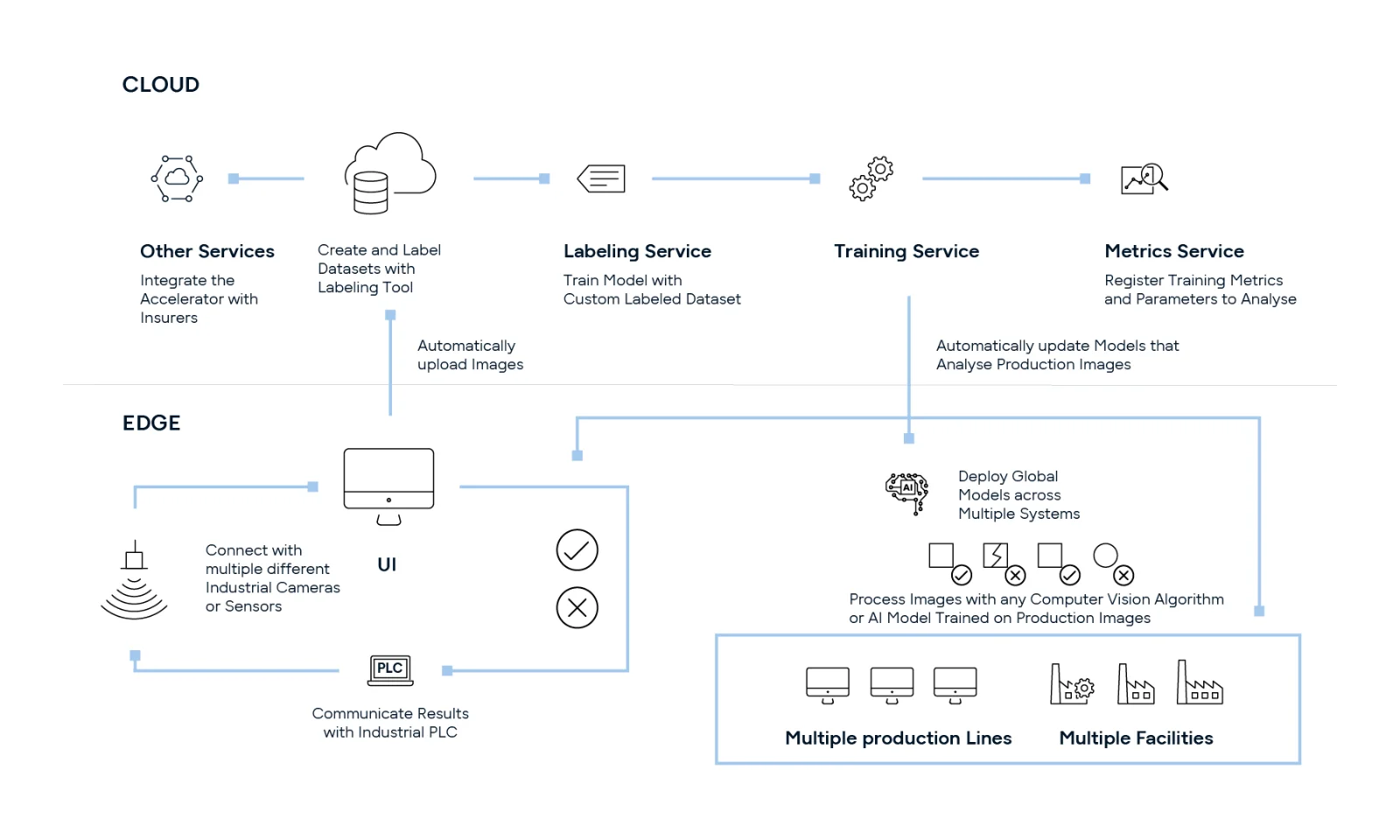

AI-powered Visual Inspection combines edge performance with cloud scalability, delivering intelligence where it’s needed most — across industries and production sites.

- Real-time processing.

Execute fast, cycle-time-compliant inspections with edge-based AI-powered defect detection. - Scalability and efficiency.

Keep quality consistent across multiple sites with cloud-based model updates. - Autonomous operations.

Give operators real-time insights and control for smarter and faster decisions. - Predictive maintenance

Combine inspection data with machine data to prevent downtime and optimize production.

Why GFT Technologies

See Precision in Action

AI for Zero-Defect Operations

What sets GFT apart is not just our technology, but our ability to turn AI into measurable value. We work side by side with clients to design inspection systems that don’t just detect defects - they transform how entire operations run.

With deep industry expertise and a track record of large-scale AI deployments, we help organizations move from pilot projects to production-ready systems.

And we don’t stop at theory - our solutions are already proving their value on production lines around the world.

Proof Points / Did you know

From Bottles to Welds to Cakes — Precision at Speed

Hot-End Bottle Inspection

A leading glass manufacturer improved hot-end quality control with AI-powered visual inspection. Within milliseconds, the system detects bottle defects in real time, ensuring only flawless products proceed. This automation reduces waste, eliminates manual errors, and increases efficiency, transforming quality control into a seamless, high-speed process.

Package Labelling Inspection

A food manufacturer implemented AI-driven label verification to ensure packaging accuracy. The system reads label contents and compares them to expected values in real time, detecting errors instantly. This automation prevents mislabeling, reduces recalls, and ensures compliance with industry regulations.

Weld Seam Inspection

An automotive supplier implemented AI-driven weld seam measurement to analyse results in real time. The system reduces inspection time from minutes to seconds, ensuring precise seam quality while increasing production speed and efficiency.

Cake Filling Inspection

A food manufacturer implemented AI-driven thermal imaging to predict the amount of cream inside cakes. This real-time analysis ensures consistent filling levels, reduces waste, and improves product quality without disrupting production.